MANUFACTURING PROCESS PREMIUM CHARCOAL

Sustainable Sourcing

We partner with certified, sustainable forestry operations to ensure our hardwood is responsibly harvested.

Rigorous Quality Control

Each batch undergoes stringent testing to verify its fixed carbon percentage, moisture content, and ash residue. We maintain strict quality standards to ensure consistency in every bag.

Kiln Carbonization

We use a controlled pyrolysis process in specialized kilns to transform the hardwood into pure charcoal. This process removes moisture and volatile compounds, leaving behind pure carbon.

Custom Packaging

We offer a variety of packaging solutions, including custom branding and sizing, to meet the specific requirements of our wholesale and retail partners.

Premium Indonesian Hardwood Charcoal Specifications

Indonesian hardwood charcoal is globally known for its high heat value, long burning duration, and clean performance. Produced from selected tropical hardwoods such as tamarind, mahogany, and acacia, our charcoal delivers consistent quality for BBQ, grilling, and industrial fuel applications.

We manufacture and export premium-grade hardwood charcoal that meets international standards — ensuring top performance for both household and commercial buyers.

Grade AA Hardwood Charcoal

Product | Hardwood Charcoal |

Size | 5cm – 20cm |

Fixed Carbon | 82,10% |

Calory | 7000 kcal / kg |

Moisture | 2,9% |

Ash Content | 3% |

Shape | Chunks/splits, sticks |

Burning Time | +4 hours no sparks, Odourless and Chemical-Free |

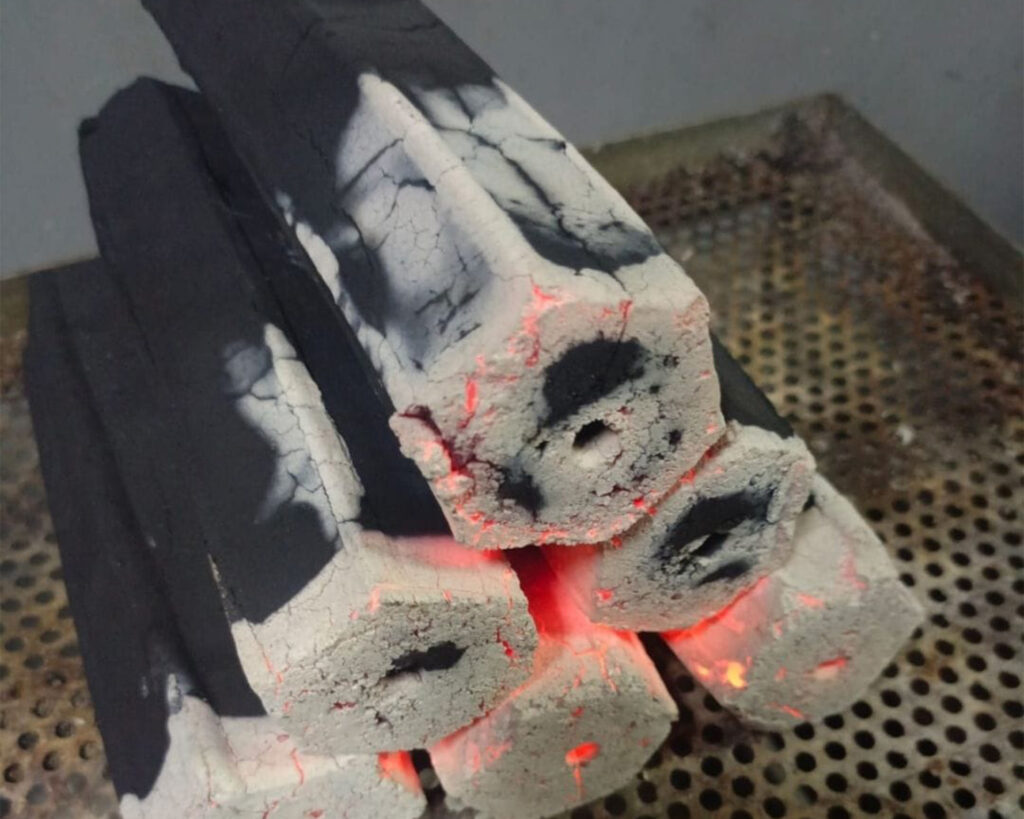

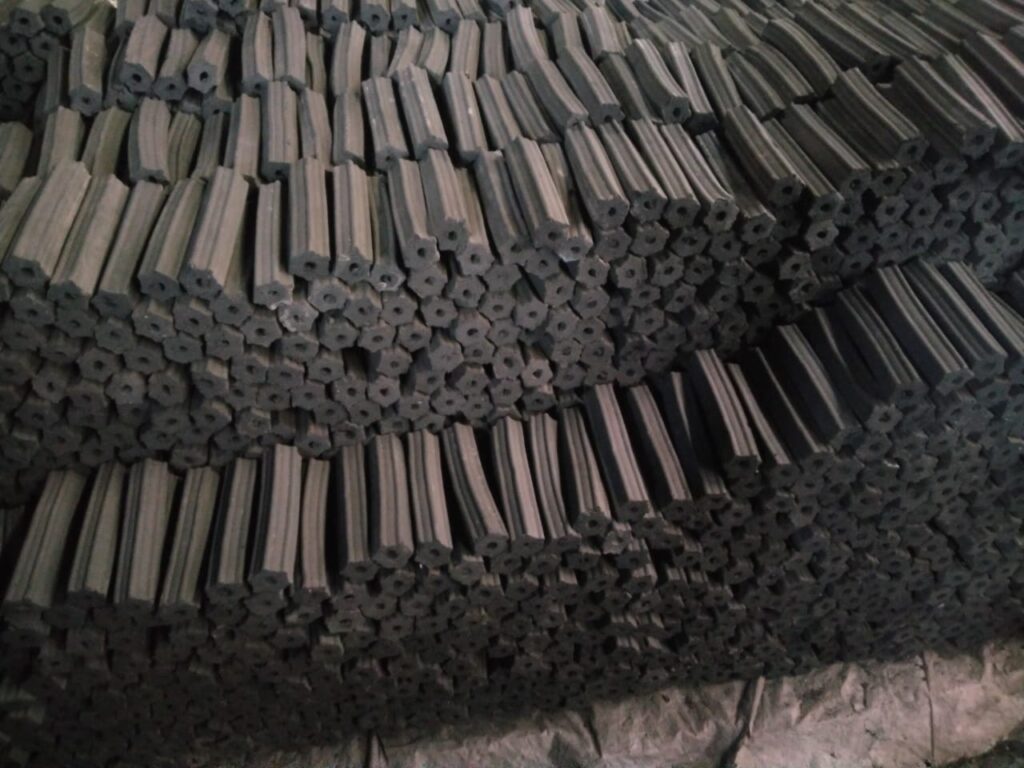

Grade AA Sawdust Charcoal

Product | Sawdust Charcoal |

Shape | Hexagonal 5cm – 15cm |

Fixed Carbon | 82,1% |

Calory | 8000 kcal / kg |

Moisture | 5-6% Max |

Ash Content | 4% |

Ash Color | White Cream Ash |

Burning Time | 6-7 hours no sparks, Odourless and Chemical-Free |

Grade AA Coffee Charcoal

Product | Coffee Charcoal |

Size | 5cm – 20cm |

Fixed Carbon | 82,10% |

Calory | 7000 kcal / kg |

Moisture | 2,9% |

Ash Content | 3% |

Shape | Chunks/splits, sticks |

Burning Time | +4 hours no sparks, Odourless and Chemical-Free |

Grade AA BBQ Coconut Charcoal Briquettes

Product | BBQ Coconut Charcoal Briquettes |

Size | 5cm – 15cm |

Fixed Carbon | 85% |

Calory | 6000-6500 kcal / kg |

Moisture | 5-7 % |

Ash Content | 3-4% |

Shape | Hexagonal |

Burning Time | +5 hours no sparks. Odourless and Chemical-Free |

Processing Time Until Loading Of Goods

1. 10 days for 20-foot containers (18 tonnes)

2. 15 days for 40-foot containers (25 tonnes)

3. Printing of inner boxes or charcoal packaging: 2-3 weeks.

4. Packaging: 3-6 days.

20″ FCL ocean container: 17.5 – 20 tonnes.

40″ FCL ocean container: 25 – 26 tonnes.

Port of Loading

1. Semarang

2. Jakarta

3. Surabaya.

4. Medan

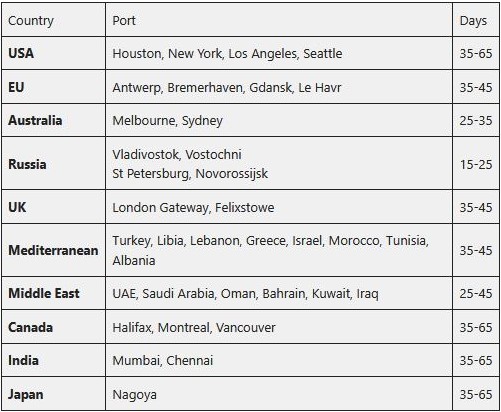

Delivery Times To Various Cities Around The World

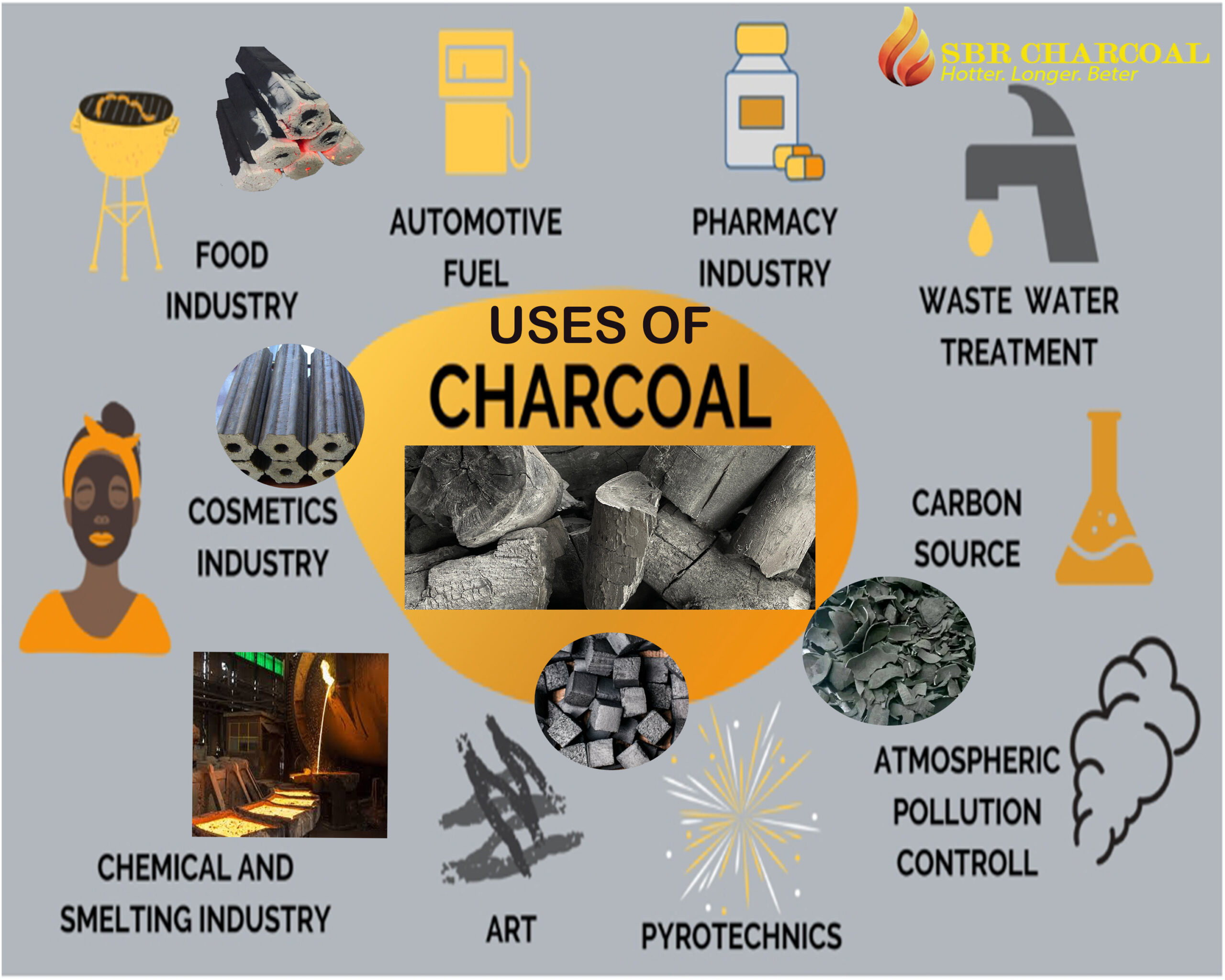

Application Of Hardwood SBR Charcoal

Hardwood charcoal, particularly in its natural lump charcoal form, is a versatile carbon-rich material used across several major sectors due to its high carbon content, clean burn, high heat output, and lack of chemical additives.

Here are the primary applications of hardwood charcoal:

I. Culinary and Residential Fuel

This is the most well-known application, especially in regions that favor traditional grilling and smoking.

- Grilling and BBQ (Lump Charcoal): Hardwood lump charcoal is the preferred choice for many grill masters because it:

- Burns Hotter: Reaches higher temperatures quickly, ideal for searing meats (the Maillard reaction).

- Burns Cleanly: Produces little to no smoke (once fully lit) and imparts a pure, smoky flavor that enhances food.

- Is All-Natural: Contains no binders, fillers, or chemical accelerants, unlike many briquettes.

- Lights Quickly and is very responsive to airflow changes, giving the user excellent temperature control.

- Home Heating: Used in fireplaces, stoves, and braziers as a smokeless and efficient domestic heating fuel.

II. Industrial and Metallurgical Applications

Historically, charcoal was the primary fuel for metallurgy, and it remains a superior component in certain industrial processes today, especially in the push for “green steel” and low-sulfur processes.

- Reducing Agent in Metallurgy: Hardwood charcoal is a high-purity source of carbon used to reduce metal oxides (like iron ore) to metallic iron and other metals in blast furnaces and smelting operations. Its low sulfur and phosphorus content is critical for producing high-pquality, purer metals.

- Smelting and Forging Fuel: Used by blacksmiths and in high-temperature kilns (for glass, crystal, or pottery) due to its ability to burn at extremely high, consistent temperatures (often exceeding).

- Chemical Feedstock: Used in the production of various chemicals, including carbon disulfide.

- Production of Activated Carbon: While coconut shell is often preferred for its microporosity, hardwood charcoal can also be a raw material for producing activated carbon, used for large-scale industrial filtration.

III. Environmental and Agricultural Uses

Charcoal has properties that make it an excellent material for air, water, and soil treatment.

- Odor and Moisture Absorption: Due to its porous structure, additive-free charcoal pieces are placed in confined spaces (refrigerators, closets, basements, toolboxes) to absorb unpleasant odors and excess moisture, helping to prevent mildew and rust.

- Soil Amendment (Biochar): When crushed and mixed into soil, biochar improves soil quality by:

- Increasing water retention and aeration.

- Providing a habitat for beneficial microorganisms.

- Balancing soil (alkaline nature).

- Improving the carbon-to-nitrogen ratio in compost heaps, reducing ammonia-like odors.

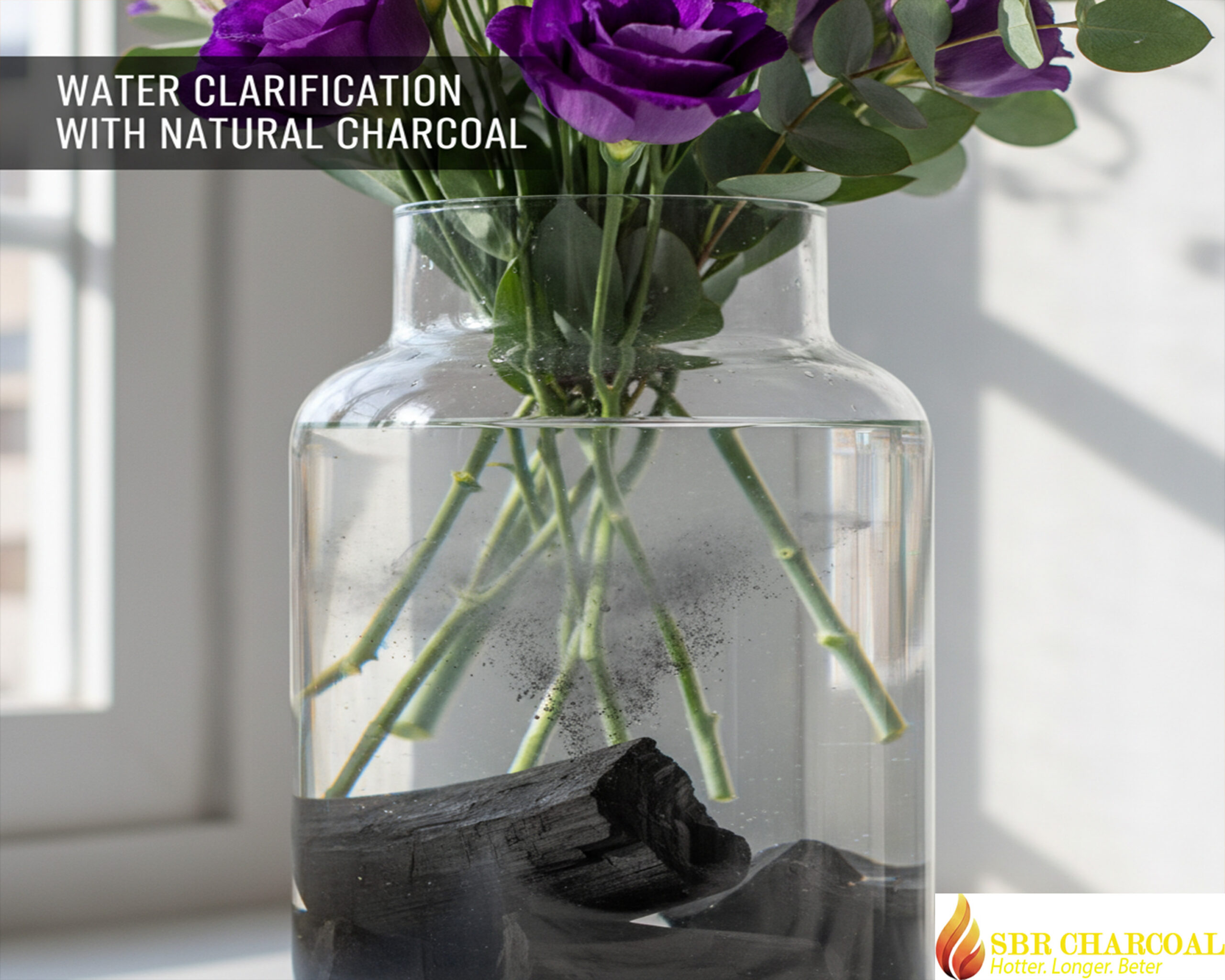

- Water Clarification: Adding a small piece of charcoal to a vase of cut flowers helps keep the water cleaner and prevents the growth of bacteria, prolonging the life of the arrangement.

IV. Niche and Specialized Uses

- Black Powder Production: A component in the manufacturing of traditional black gunpowder, where charcoal from specific woods (like alder or buckthorn) is valued for its specific carbon content.

- Art and Drawing: Hardwood charcoal sticks are a classic medium for drawing, sketching, and shading.

- Polishing and Grinding: Finely ground charcoal powder is used in certain industrial processes for grinding and polishing precision parts.

We partner with certified, sustainable forestry operations to ensure our hardwood is responsibly harvested.