MANUFACTURING PROCESS SBR CHARCOAL

Sustainable Sourcing

We partner with certified, sustainable coconut farmers operations to ensure our coconut trees is responsibly harvested.

Rigorous Quality Control

Each batch undergoes stringent testing to verify its fixed carbon percentage, moisture content, and ash residue. We maintain strict quality standards to ensure consistency in every bag.

Kiln Carbonization

We use a controlled pyrolysis process in specialized kilns to transform the coconut shell into pure charcoal. This process removes moisture and volatile compounds, leaving behind pure carbon.

Custom Packaging

We offer a variety of packaging solutions, including custom branding and sizing, to meet the specific requirements of our wholesale and retail partners.

🔥 Spesifications Premium SBR Coconut Charcoal (Shisha or Hookah)

SBR Coconut Charcoal is a premium-grade charcoal made from 100% natural Indonesian coconut shells, carefully processed to deliver long burning time, high heat, and clean performance.

We manufacture and export coconut charcoal briquettes and natural lump charcoal to meet international standards for BBQ and shisha (hookah) markets worldwide.

Grade AA Coconut Charcoal Briquettes Hookah

Product | Coconut Charcoal Briquettes Hookah |

Composition | 100% selected coconut shell charcoal |

Fixed Carbon | 85% |

Calory | 6800 – 7200 kcal / kg |

Moisture | 5%-6% Max |

Ash Content | 2%-2.5% |

Ash Color | White Cream Ash |

Burning Time | +2 hours no sparks, Odourless and Chemical-Free |

Grade AA Coconut Shell Charcoal

Product | Coconut Shell Charcoal |

Volatile Matter | Not more than 15% |

Fixed Carbon | 82% – 85% |

Calory | 6800-7200 kcal / kg |

Moisture | 2,9% |

Ash Content | 3% |

Composition | 100% selected coconut shell charcoal |

Burning Time | 2 hours no sparks, Odourless and Chemical-Free |

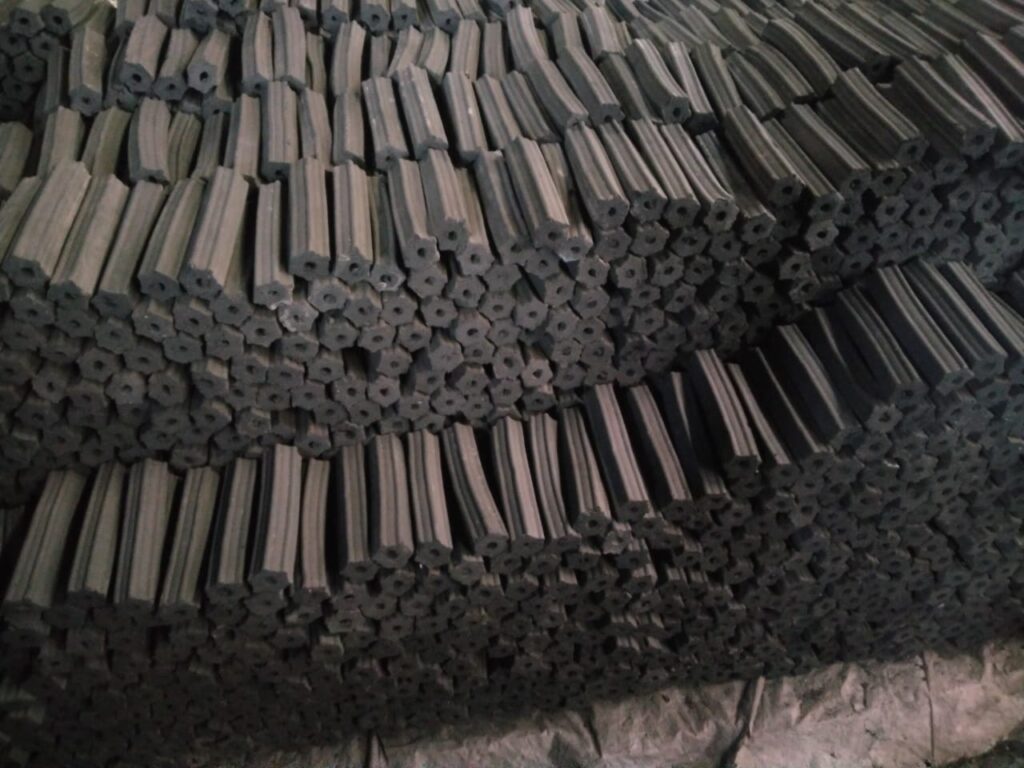

Grade AA BBQ Coconut Charcoal Briquettes

Product | BBQ Coconut Charcoal Briquettes |

Size | 5cm – 15cm |

Fixed Carbon | 85% |

Calory | 6000-6500 kcal / kg |

Moisture | 5-7 % |

Ash Content | 3-4% |

Shape | Hexagonal |

Burning Time | +5 hours no sparks. Odourless and Chemical-Free |

Processing Time Until Loading Of SBR Chacoal Coconut.

1. 7 days for 20-foot containers (16 tonnes)

2. 9 days for 40-foot containers (22 tonnes)

3. Printing of inner boxes or charcoal packaging: 2-3 weeks.

4. Packaging: 3-6 days.

20″ FCL ocean container: 15 – 17 tonnes.

40″ FCL ocean container: 20 – 22 tonnes.

Port of Loading

1. Semarang

2. Jakarta

3. Surabaya.

4. Medan

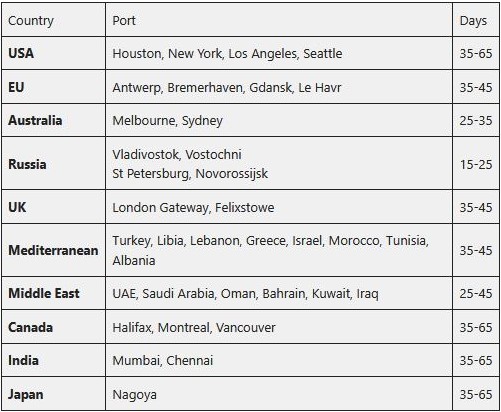

Estimated Arrival To Various Cities Around The World

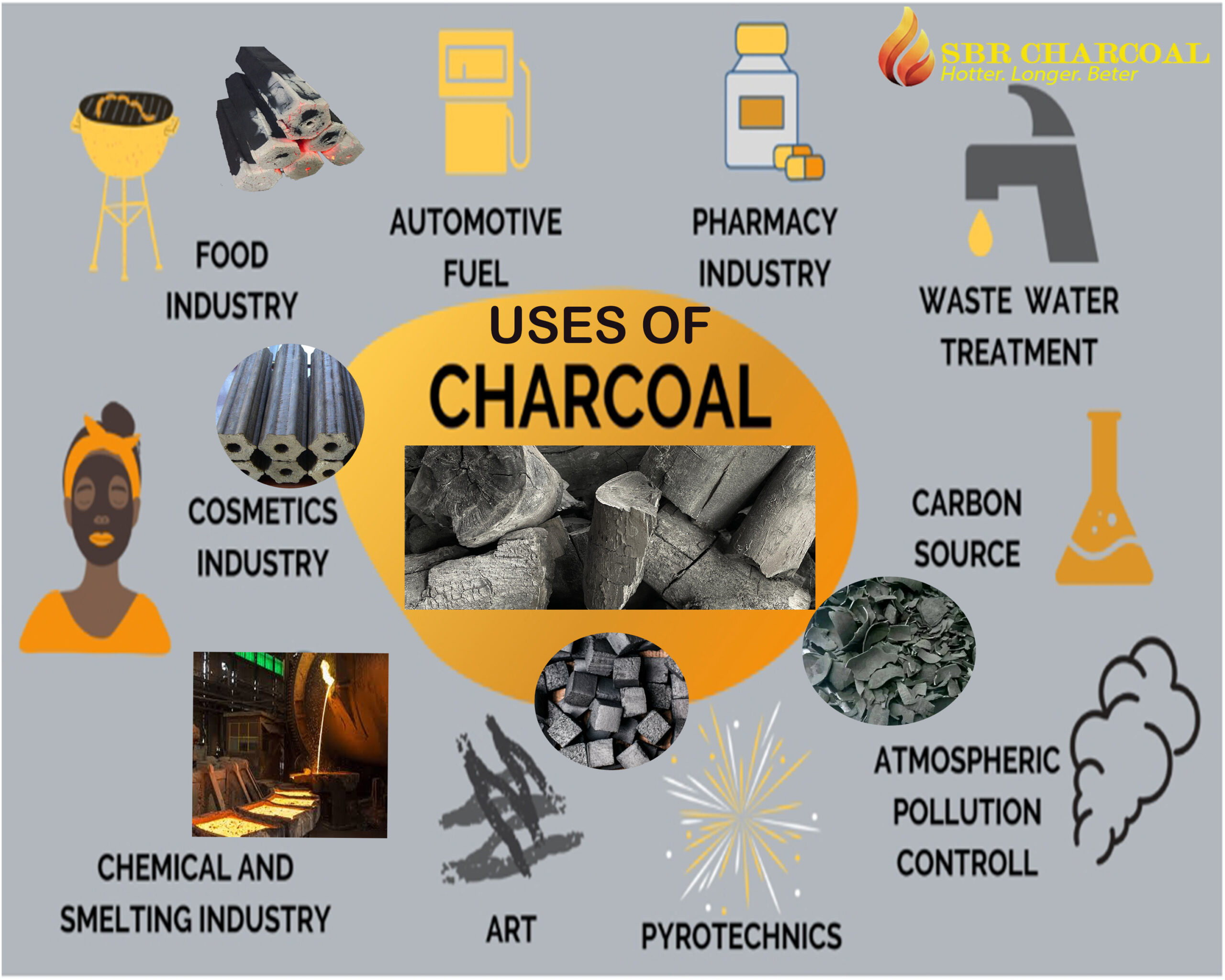

Application Of Coconut PREMIUM SBR Charcoal

The applications of coconut charcoal are incredibly diverse, spanning industrial, environmental, consumer, and health sectors. Derived from the carbonization of coconut shells (an agricultural waste product), this Eco-friendly material is highly valued, especially when processed into its porous form, Activated Carbon.

Here are the major applications of coconut charcoal:

- Activated Carbon Production (The Primary Use)

The most significant application of coconut charcoal is its conversion into Activated Carbon (AC). Due to its unique microporous structure, coconut shell AC has an extremely large internal surface area, making it highly effective at adsorption (binding molecules to its surface).

- Environmental & Filtration

- Water Purification: Used in municipal, industrial, and household water filters (like those in refrigerators and pitcher filters) to remove impurities, chlorine, volatile organic compounds (VOCs), pesticides, and bad odors/tastes from drinking water.

- Air Purification: Employed in air filters and gas masks to absorb odors, smoke, and pollutants (like VOCs) in homes, offices, and industrial settings.

- Wastewater Treatment: Used in industrial processes to clean and purify effluent before it is discharged.

- Oil Spill Cleanup: Its high porosity allows it to effectively absorb oil and other contaminants from water surfaces.

- Industrial & Chemical

- Gold Recovery (Mining): Used extensively in the gold mining industry (specifically the CIP/CIL process) to efficiently adsorb and recover microscopic gold particles from ore slurries.

- Food and Beverage Processing: Used to decolorize and purify liquids such as sugar syrups, juices, alcoholic beverages (like spirits and wine), and edible oils.

- Pharmaceutical and Chemical Industry: Used as a catalyst support or to remove impurities in various chemical manufacturing processes.

- Fuel and Heat Source

Coconut charcoal is prized as a clean, sustainable fuel source due to its high fixed carbon content, low ash, and long, consistent burn time.

- BBQ and Grilling: Coconut charcoal briquettes (often cubic or hexagonal) are a premium alternative to wood or coal briquettes. They burn hotter, longer, and produce very little smoke or odor, allowing the true flavor of the food to shine.

- Hookah/Shisha: Specifically formed coconut charcoal cubes are the standard for premium shisha sessions. They provide steady, odorless heat for an extended period.

- Industrial Fuel: Used in various industries (like brick kilns, furnaces, and metal smelting) as an environmentally friendly and high-efficiency fuel source.

III. Health, Personal Care, and Cosmetics

The detoxifying and adsorbent properties of activated coconut charcoal have made it a popular ingredient in wellness and beauty products.

- Emergency Poison Control: Activated charcoal is used in emergency rooms to treat certain types of poisoning or drug overdoses, as it can bind toxins in the stomach before the body absorbs them.

- Digestive Health: Used as a dietary supplement to help alleviate gas, bloating, and indigestion by binding to gas-producing byproducts in the gut.

- Teeth Whitening: Found in natural toothpastes and powders, it helps remove surface stains and plaque by adsorption.

- Skincare and Cosmetics: Used in face masks, cleansers, and soaps to draw out excess oil, dirt, and impurities from the skin, helping to reduce acne and clear pores.

- Agricultural Applications (Biochar)

When used in agriculture, coconut charcoal is often referred to as biochar and offers significant soil benefits.

- Soil Amendment/Conditioner: Biochar improves soil health by enhancing water retention, increasing aeration, and raising the level of acidic soil.

- Nutrient Retention: Its porous structure helps the soil hold onto essential nutrients, reducing the need for chemical fertilizers.

- Promoting Plant Growth: Creates a favorable environment for beneficial microorganisms, leading to healthier crops and increased yields.